A1

100%

A1

100%

B1

100%

B1

100%

B2

100%

B2

100%

B3

100%

B3

100%

B4

100%

B4

100%

C1

100%

C1

100%

D1

100%

D1

100%

D2

100%

D2

100%

E1

100%

E1

100%

E2

100%

E2

100%

E3

100%

E3

100%

CONCLUSIONES

100%

CONCLUSIONES

100%

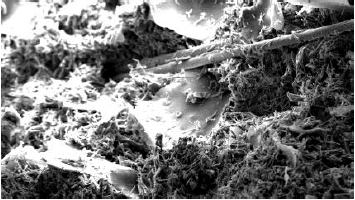

Characterisation of polyurethane waste (PU) and definition of the processing parameters

The processing parameters of seven polyurethane foam wastes (PU) with different formats and origins have been characterised and defined:

- Insulation panels from the refrigeration and construction industry (P, B, I, EW, SHY)

- Car seats (SG, SHY)

- Automobile industry production waste (A, AT)

01

Análisis elemental CHNS

02

Análisis TGA03

Microscopía electrónica de barrido

04

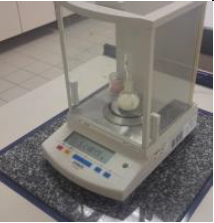

Densidad real y aparente05

Capacidad absorción de agua

06

Análisis 3D TAC07

Ensayo de lixiviación

08

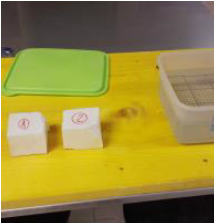

Difracción de rayos láser Sample cut

Sample cut

Grinding of the sample

Grinding of the sample

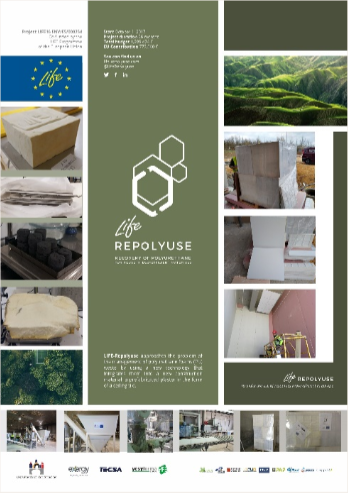

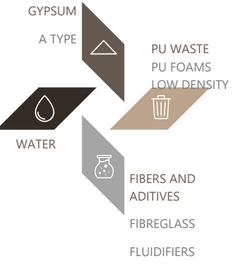

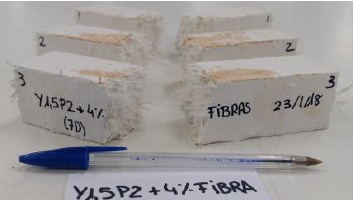

Integration of polyurethane waste in new gypsum materials

The characterisation tests have been carried out on the samples in fresh and hardened state with the substitution of gypsum by PU waste. The incorporation of each of the characterised wastes into Action A has been tested, and the mixtures have been optimised to achieve the ideal dosage for the full-scale manufacture of the prototype.

2º Results

2º Results

3º Integration

3º Integration

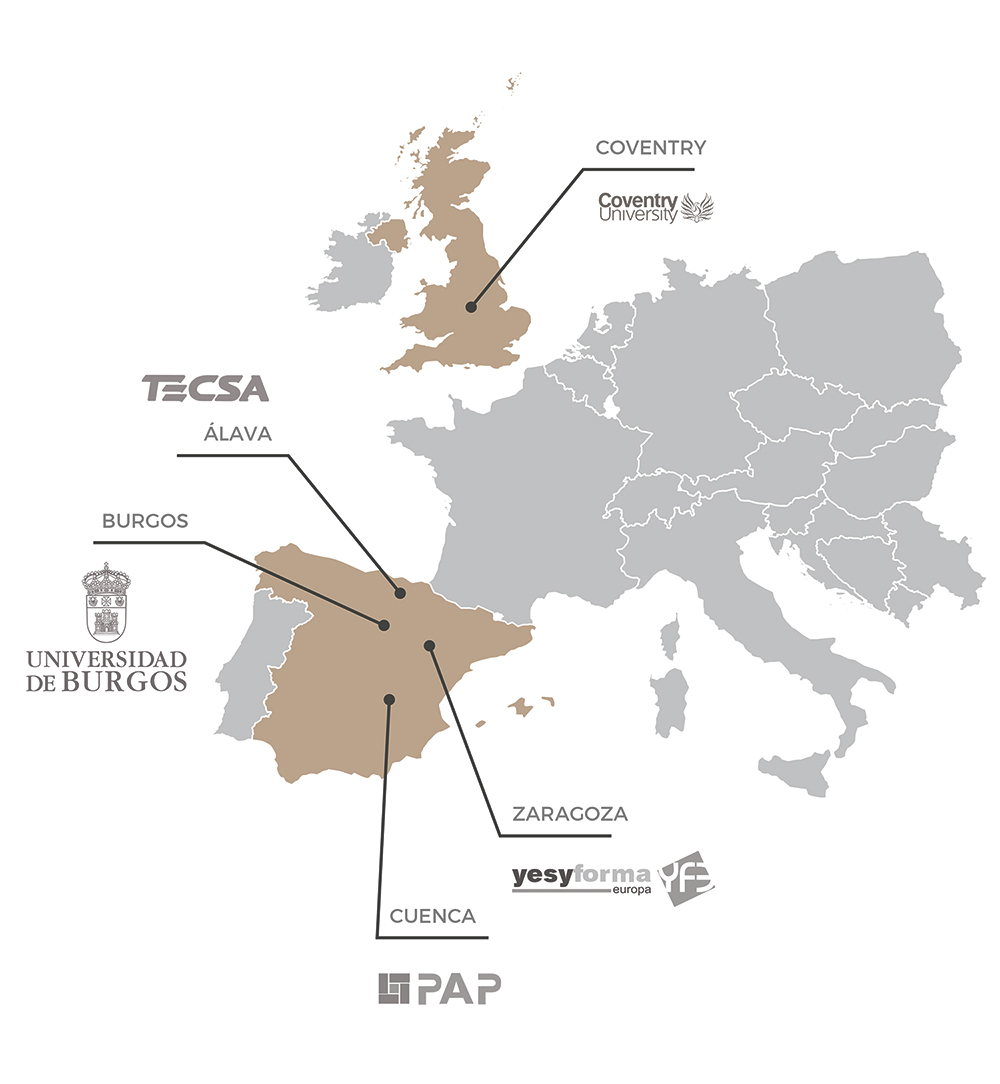

Product manufacture

In order to manufacture the new ceiling tiles, YESYFORMA has developed a new prototype to achieve optimal mixture of the raw materials. The new production line has produced the 950 m2 of ceiling tiles for the Installation of a removable false ceiling in the 3 Demo-sites of the Project: Coventry (United Kingdom) United Kingdom), Burgos and Vitoria (Spain). The new material has been tested in accordance with the regulations of the sector to certify its technical viability, and it has the CE Marking. The new product has been protected through a Utility Model owned by the UBU, exclusively licensed to the company YESYFORMA.

Pilot test in buildings of different typology

The new tiles (gypsum-polyurethane) have been placed in three different buildings (one is a new building and the other two are rehabilitations). The aim is to monitor the energy performance, comparing it with conventional gypsum tiles. The monitoring area is 200 m2 in the Technology Park of Araba in Álava (Spain), 350 m2 in the Demo-site of the Higher Polytechnic School in Burgos (Spain) and 400 m2 in the Sir John Laing Building at the University of Coventry (United Kingdom).

Reinforcement of environmental policies. Replicability-transferability

The regulatory Framework for the case of the waste managed in the LIFE-REPOLYUSE Project is the following:

- Clean PU foam cuttings (by-products). Order APM/397/2018, of 9th April.

- Polyurethane waste with other possible waste, destined for recovery operations. Law 22/2011, of 28 July, on waste and contaminated soil.

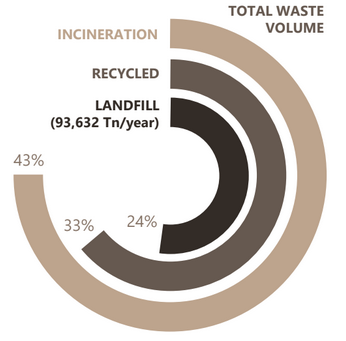

In Europe, the market for registerable ceiling tiles is approx. 3.5 million m2/year. And every year 93,632 tons of polyurethane foam waste is deposited in landfills. The exhaustive analysis of the location of generating plants and prefabricated industries guarantees the flow of generating-manufacturing waste in all cases.

The replicability of the project is guaranteed thanks to our manufacturing partner YESYFORMA, owner of the licence to use the new product. The new product has the CE mark and offers important functional and environmental advantages. Likewise, the plasterboard industry has shown interest in replicating the LIFE- REPOLYUSE technology.

With the "Application guide of the integration process of the polyurethane waste in a gypsum prefabricated", the manufacturers of these materials will have enough tools to understand the simplicity of the industrial process and will be able to plan the application of this new technology in their companies.

This "Updated Manual of Environmental Policies", presents the analysis of the specific regulations for the treatment of polyurethane waste and the environmental policies of companies, within the European Union.

The document has been reviewed by the Consejería de Fomento y Medio Ambiente de la Junta de Castilla y León, and by the Federación Española de la Recuperación y el Reciclaje.

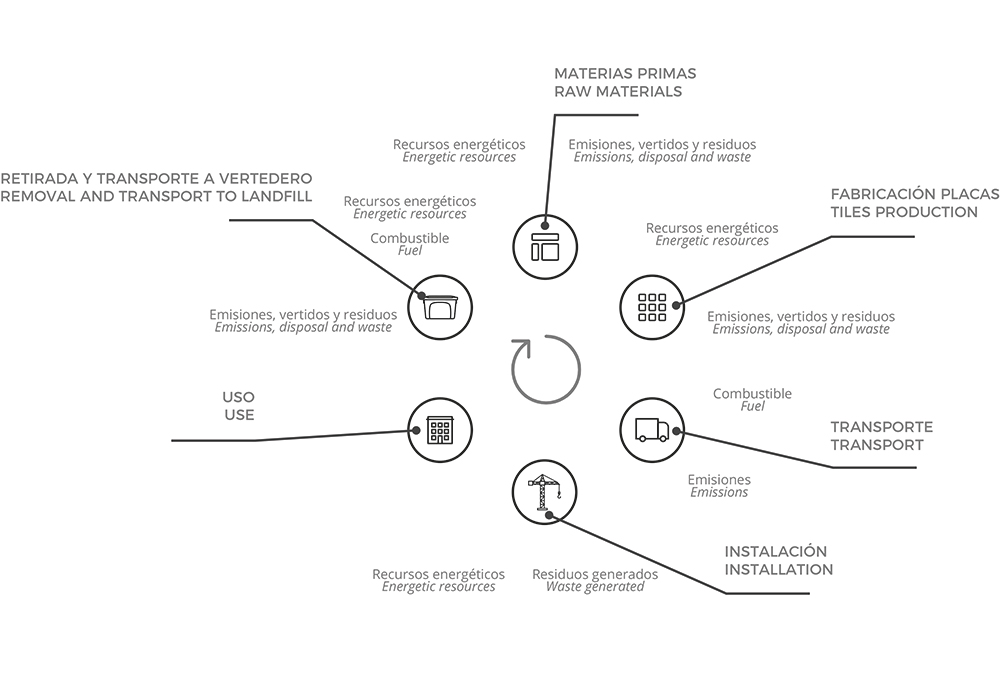

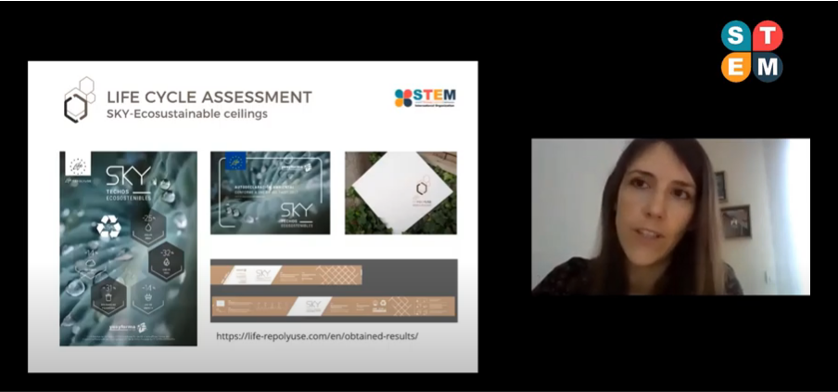

Technical-Environmental Monitoring (LCA) and Socio-Economic Analysis (LCC)

The 3 buildings (Coventry, Vitoria and Burgos) have an environment of monitoring IoT technology that allows real-time measurement of humidity and temperature variables related to the comfort of the monitored spaces. Work has been done with the State Meteorological Agency (AEMET), to relate the parameters of indoor comfort with the meteorological data from outside.

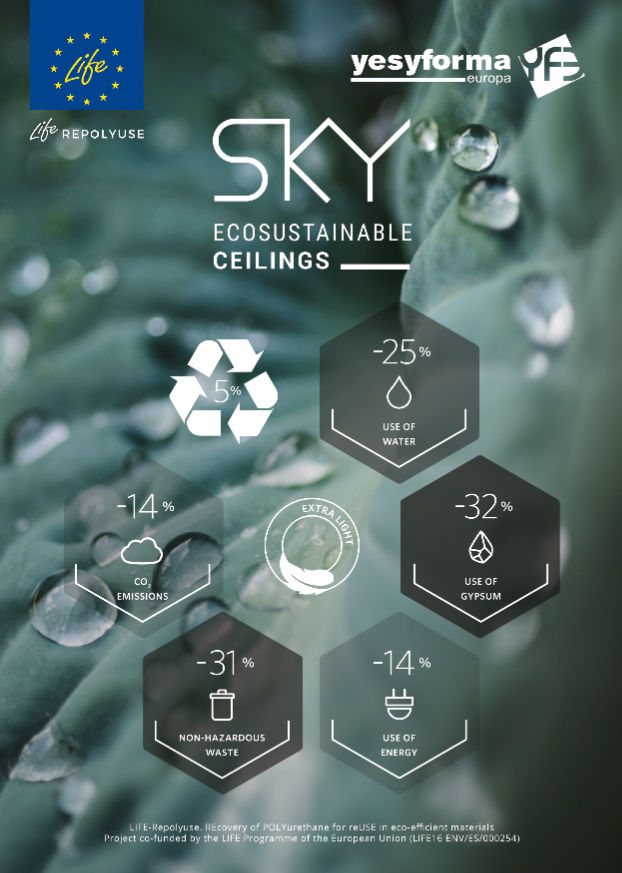

The Life Cycle Analysis has been carried out in order to make a comparative analysis between the LIFE-REPOLYUSE tile and the standard tile manufactured by the same company, according to ISO 14044:2006 The new LIFE-REPOLYUSE product could recover in raw materials a (25.71%) saving in water and a (31.6%) reduction in gypsum consumption. The new material, compared to a standard product, has significant improvements in CO2 savings (14%) and lower energy consumption in its manufacturing processes (14%).

The new product SKY Eco-Sustainable Ceilings has shown to have improved technical performance and lower environmental impact in its Life Cycle phases, compared to standard gypsum board. For this reason, the new product already has an Environmental Product Self-Declaration (Type II Ecolabel).

The new tiles (gypsum-polyurethane) have been placed in three different buildings (one is a new building and the other two are rehabilitations).

DEMO BURGOS (SPAIN) and DEMO COVENTRY (UK)

2018‐2019: Monitoring of Standard Tiles

2019‐2020: Monitoring of Life-Repolyuse Tiles

DEMO VITORIA (SPAIN)

2019‐2020: Simultaneous monitoring Standard Tile and Life-Repolyuse Tiles

The 3 buildings have a monitoring environment with IoT technology that allows real-time measurement of variables related to the comfort

| ºC Temperature | ||||||

|---|---|---|---|---|---|---|

| Place | Year | Temp. Int. | Temp. Ext. | Dif. Temp. Int. | Dif. Temp. Ext. | Dif. Temp. |

| Burgos | 2019 (Control) | 16.06 | 3.84 | 1.86 | 1.64 | 0.22 |

| Burgos | 2020 (Gypsum-PU) | 17.92 | 5.48 | |||

| Coventry | 2019 (Control) | 18.18 | 5.99 | 2.34 | 1.34 | 1.00 |

| Coventry | 2020 (Gypsum-PU) | 20.52 | 7.33 | |||

| Vitoria | 2020 (lisa) | 6.50 | 4.21 | 0.15 | 0.02 | 0.13 |

| Vitoria | 2020 (Gypsum-PU) | 6.65 | 4.23 | |||

| % Humidity | ||||||

|---|---|---|---|---|---|---|

| Place | Year | Hum. Int. | Hum. Ext. | Dif. Hum. Int. | Dif. Hum. Ext. | Dif. Hum. |

| Burgos | 2019 (Control) | 33.20 | 76.32 | 8.07 | 9.13 | 1.14 |

| Burgos | 2020 (Gypsum-PU) | 41.27 | 85.45 | |||

| Coventry | 2019 (Control) | 37.55 | 86.24 | 5.20 | -1.96 | -7.16 |

| Coventry | 2020 (Gypsum-PU) | 42.75 | 84.28 | |||

| Vitoria | 2020 (lisa) | 74.63 | 85.70 | -0.22 | -0.05 | 0.16 |

| Vitoria | 2020 (Vasari) | 74.41 | 85.65 | |||

Data obtained with the collaboration of the Agencia Estatal de Metorología (AEMET)

CONTROLLED ENVIRONMENT

DEMO BURGOS (SPAIN)

Weekend from January to March 2018 and 2019

DEMO COVENTRY (SPAIN)

Weekend from January to March 2018 and 2019

DEMO VITORIA (SPAIN)

January 2019 to January 2020 (in progress)

At the comfort level, the new Life-Repolyuse tiles have a better differential temperature between the outside and the inside temperature of the space in which they are located.

Dissemination and communication of results

The dissemination and communication of the project results is being carried out through publications, informative posters, brochures, T-shirts and promotional accessories, biannual newsletters and through the project's website and social networks.

Project dissemination activities and publications

Publications

- 2 scientific paper

- 1 article in industry magazines

- Gutiérrez, S., Junco, C., Calderón, V., Rodríguez , A., Gadea, J. «Design and Manufacture of a sustainable Lightweight Prefabricated Material Based on Gypsum Mortar with semi-Rigid Polyurethane Foam Waste«. International Congress on Polymers in Concrete (ICPIC 2018) M.M.Reda Taha (ed.), (2018)./(pp. 449- 455). ISBN: 978-3-319-78174-7

- Raúl Gómez-Rojo, Lourdes Alameda, Ángel Rodríguez, Verónica Calderón and Sara Gutiérrez-González. Characterization of Polyurethane Foam Waste for Reuse in Eco-Efficient Building Materials. Polymers 2019, 11, 359; doi:10.3390/polym11020359

Dissemination

- 5 dissemination videos of the Project

- 2 Radio interviews

- Program UBUInvestiga

Technical dissemination of project activities

The technical dissemination of the LIFE-REPOLYUSE project activities is carried out through the elaboration of children and youth workshops and the participation in dissemination events, conferences, congresses and seminars.

Children’s workshop. University of Burgos. Burgos (Spain)

Children’s workshop. University of Burgos. Burgos (Spain)

XLVI General Assembly of ATEDY. Madrid (Spain)

XLVI General Assembly of ATEDY. Madrid (Spain)

Innovation Forum in Architecture, Construction and Rehabilitation. Bilbao (Spain)

Innovation Forum in Architecture, Construction and Rehabilitation. Bilbao (Spain)

European researchers night. Burgos (Spain)

European researchers night. Burgos (Spain)

X Congress JIP 2019 “Young polymer researchers”. Burgos (Spain)

X Congress JIP 2019 “Young polymer researchers”. Burgos (Spain)

Final Event LIFE ICIRBUS-4INDUSTRIES Project

Final Event LIFE ICIRBUS-4INDUSTRIES Project

3 rd RILEM Spring Convention 2020. University of Minho. Guimarães (Portugal)

3 rd RILEM Spring Convention 2020. University of Minho. Guimarães (Portugal)

Plastics Circularity Multiplier - Online Conference 2020

Plastics Circularity Multiplier - Online Conference 2020

Recycling and Waste Management Event 2021 (STEM International Organization)

Recycling and Waste Management Event 2021 (STEM International Organization)

«ICPIC18» Congress “Polymers for Resilient and Sustainable Concrete Infrastructure”. Washington (EE.UU.)

«ICPIC18» Congress “Polymers for Resilient and Sustainable Concrete Infrastructure”. Washington (EE.UU.)

10th International Exhibition and Conference "Save the Planet-Waste Management and Recycling». Sofia (Bulgaria)

10th International Exhibition and Conference "Save the Planet-Waste Management and Recycling». Sofia (Bulgaria)

Workshop “The future of the construction sector and R&D”. University Carlos III. Madrid (Spain)

Workshop “The future of the construction sector and R&D”. University Carlos III. Madrid (Spain)

Technical conference “Ideas for Balancing the World”

Technical conference “Ideas for Balancing the World”

New materials that sustain the world

New materials that sustain the worldFinal Project Event

Project management and coordination

The project follows an established Management Plan to ensure that the technical-financial objectives are met on time. Regular meetings of the consortium are held to share the results obtained and to establish the following tasks to be carried out. At the beginning of 2019, the Mid-term report of the project was presented to the European Commission and in February 2020 the Progress-report.

Kick-Off Meeting. EPS, Burgos (Spain) 07/11/2017

Kick-Off Meeting. EPS, Burgos (Spain) 07/11/2017

Visit to YESYFORMA in Zaragoza, Spain 29/11/2017

Visit to YESYFORMA in Zaragoza, Spain 29/11/2017

4th Progress meeting Burgos (Spain) 08/10/2019

4th Progress meeting Burgos (Spain) 08/10/2019

2nd Progress meeting, Bilbao (Spain) 13/03/2018

2nd Progress meeting, Bilbao (Spain) 13/03/2018

2nd Progress meeting, EPS, Burgos (Spain) 19/09/2019

2nd Progress meeting, EPS, Burgos (Spain) 19/09/2019

Visit to PAP (Paneles Aislantes Peninsulares) facilities in Cuenca (Spain) 28/11/2017

Visit to PAP (Paneles Aislantes Peninsulares) facilities in Cuenca (Spain) 28/11/2017

Working meeting with YESYFORMA. EPS, Burgos (Spain) 21/02/2018

Working meeting with YESYFORMA. EPS, Burgos (Spain) 21/02/2018

3rd Progress meeting, EPS, Burgos (Spain) 01/02/2019

3rd Progress meeting, EPS, Burgos (Spain) 01/02/2019

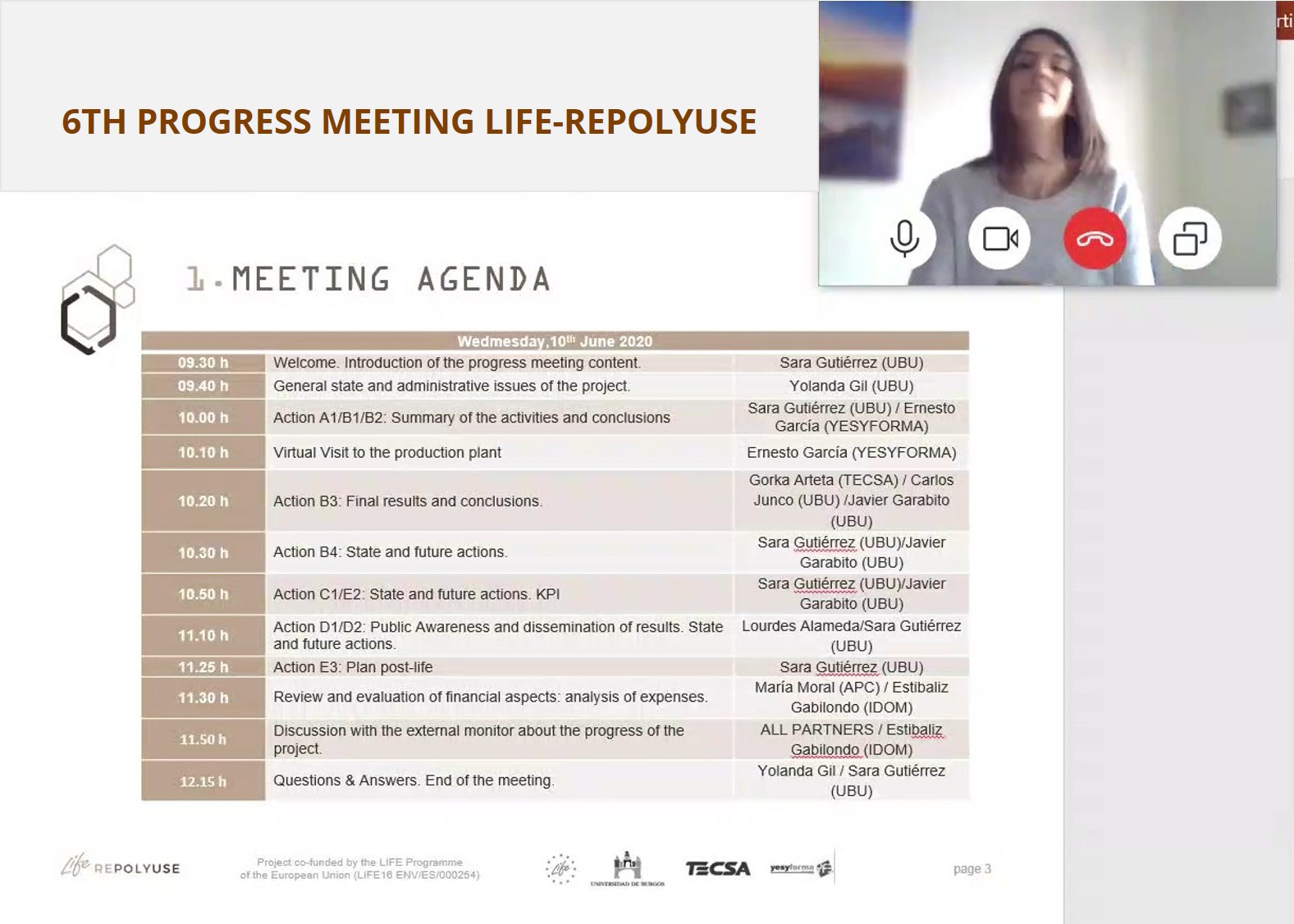

6th Progress meeting - Online (10/06/2020)

6th Progress meeting - Online (10/06/2020)

7th Progress meeting - Online (06/11/2020)

7th Progress meeting - Online (06/11/2020)

Final Monitoring Meeting-Virtual (03/12/2020)

Final Monitoring Meeting-Virtual (03/12/2020)

Indicators

A GAP analysis is being carried out between the KPIs defined in the initial phase of the project and the real KPIs estimated after the results obtained in the LCA.

| ENVIRONMENTAL INDICATORS | INITIAL PHASE (UE estimated, by year) |

AT THE END OF THE PROJECT (Indicator value) |

3 YEARS AFTER THE PROJECT (Indicator value) |

||

|---|---|---|---|---|---|

| Reduction of greenhouse gas emissions (GHG) | |||||

| CO2 LIFE-REPOLYUSE emission for Ceiling Tile Production Recovery | Estimation EU “Standard” Ceiling Tile CO2 emission for Production 22,708 tons CO2 eq/year | Recovery: 1.191 tons CO2 eq (19.32% Save) | Recovery: 263.340 tons CO2 eq (19.32% Save) | ||

| CO2 LIFE-REPOLYUSE emission for Building Recovery * *Pending of energetic simulation | 0.001 tons CO2 eq/year | 0.210 tons CO2 eq/year | |||

| Waste managment | |||||

| PU Foam Waste from Ceiling Tile Production Recovery | Estimation EU: 93,632 tons/year | 0.333 tons | 75 tons | ||

| Better use of natural resources | |||||

| Gypsum Consumption Recovery | Estimation EU 14,805 tons/year for “Standard” Tile Production Recovery | Recovery: 1.86 tons (31.6% Save) | Recovery: 411.16 tons (31.6% Save) | ||

| Water Consumption Recovery | Estimation EU 20,530 m3/year for “Standard” Tile Production Recovery | Recovery: 5.79 m3 (25.71% Save) | Recovery: 1,278.90 m3 (25.71% Save) | ||

| Energy Consumption for Ceiling Tile Production Recovery | Estimation EU “Standard” Ceiling Tile energy consumption for Production 91.47 (MkWh /year) | Recovery: 4,783.25 kWh (16.6% Save) | Recovery: 1.057 MkWh (16.6% Save) | ||

| Energy for Building Recovery. *Pending of energetic simulation | |||||

| Sustainable land use | |||||

| Resource efficiency - Soil | Estimation EU Soil intended for landfill (polyurethane foam waste from Production waste: 2.1 km2 per year | Recovery: 7.30 m2 | Recovery: 1,615.38 m2 | ||

Plan post life

The Project Consortium is developing a Post-Life Communication Plan and an Exploitation Plan, for the dissemination of the methodologies and results of the Project after its conclusion.

Conclusions of the work carried out

- In the phase of Characterization of PU waste and processing parameters, it has been possible to classify low-density polyurethane foam waste according to its origin. The interest of the companies generating polyurethane waste has led to the extension of the study, analysing a total of 7 polyurethane foams, some classified as by-products and others as waste. The technical data sheets of all of them give information about their possible use in different construction materials

- The integration of PU waste into the matrix of new gypsum materials is feasible, optimizing the dosage of full-scale mixtures in the production phase. The results obtained after the tests are suitable for the manufacture of recordable gypsum-PU ceiling tiles.

- The LIFE-REPOLYUSE technology has been successfully integrated into the production line of the YESYFORMA precast plant to produce new gypsum-PU tiles. The new product already has CE Marking and the Eco Label and is expected to be marketed within the framework of the Utility Model, owned by the University of Burgos with an Operating License to the company YESYFORMA EUROPA.

- The new gypsum-PU ceiling tiles are perfectly integrated in the different pilot buildings, in terms of ease of execution, aesthetics and safety. The 3 buildings have an environment of monitoring IoT technology that allows real-time measurement of humidity and temperature variables related to the comfort of the monitored spaces.

- Compared to conventional tiles, the new gypsum-PU tiles have the best reaction to fire classification according to the Eurocode (A1), maintain the acoustic absorption capacity, reduce the weight of the tiles (32%) and decrease the thermal conductivity (24%), which translates into an improvement of approximately 8% in the energy level of the building in which they are integrated.

- The new product LIFE-REPOLYUSE could recover 75 tons of polyurethane foam waste in its first years of launch, which translates into a lower expenditure of raw materials; (25.71%) water savings and a reduction of (31.6%) in gypsum. The Life Cycle Analysis of the new product LIFE- REPOLYUSE has concluded that the new material, compared to a standard product, has significant improvements in CO2 savings (14%) and lower energy consumption in its manufacturing processes (14%). It could also avoid dumping in 1615 m3 of soil.

- An analysis of the European market for gypsum tiles for ceilings that can be registered, the new tiles- PU, the amount of polyurethane foam waste generated in Europe, as well as the market viability of the new product, concludes that there is potential for replication and transferability in Spain, Portugal and Italy.

- The technical dissemination and communication of results has allowed important collaborations with companies in the construction sector, and with manufacturers and associations in the field of gypsum. Likewise, the Project has had an impact on the youngest public, promoting interest in the recycling and reuse of waste. The construction sector is committed to new eco-efficient materials; a reflection of a society that is increasingly aware of preserving and recovering the environment.

- The construction sector is committed to new eco-efficient materials; a reflection of a society that is increasingly aware of preserving and protecting the environment.